Vacuum Thermal Gravimetric Analyzer

Vacuum Thermal Gravimetric Analyzer (VTG) is an instrument that measures temperature-mass relationships of materials under high-vacuum conditions using thermogravimetric analysis. It continuously records mass changes as functions of temperature, time, and vacuum level under programmed temperature control.

When heated substances experience sublimation, vaporization, gas evolution, or dehydration, their mass changes, causing deviations from linear thermogravimetric curves. Analyzing these curves reveals transformation temperatures and quantifies mass loss. When coupled with online mass spectrometry (MS), it further identifies the composition and structure of evolved substances.

Conventional thermogravimetric analyzers typically operate in gaseous environments (e.g., pure nitrogen/oxygen), where gas interactions may affect mass transport mechanisms and introduce artifacts. This limits mechanistic studies. Vacuum thermogravimetry is essential when investigating materials in gas-free environments.

Research shows significant discrepancies between thermogravimetric curves obtained in inert atmospheres versus vacuum conditions. Studying these differences provides deeper insights into material thermal properties and yields more valuable data.

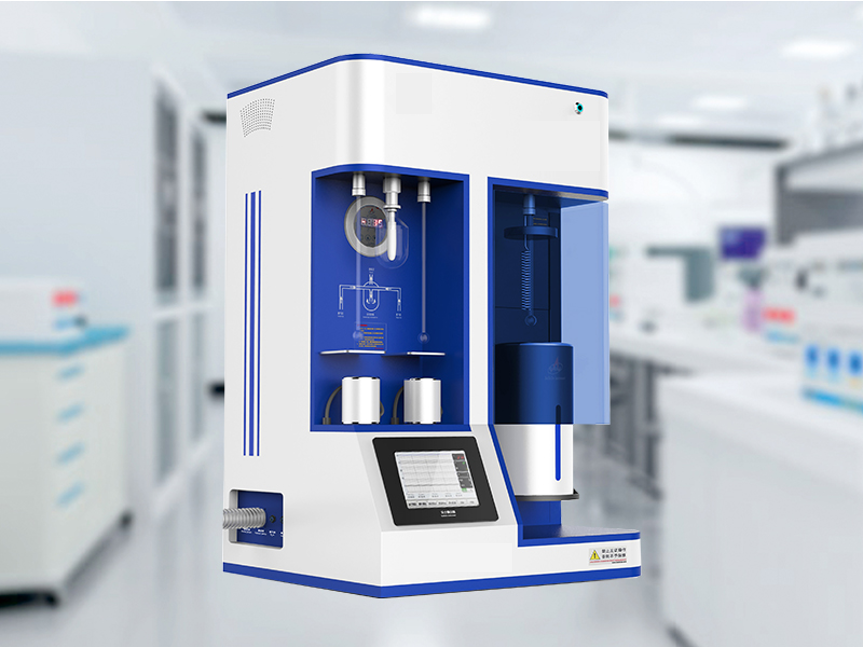

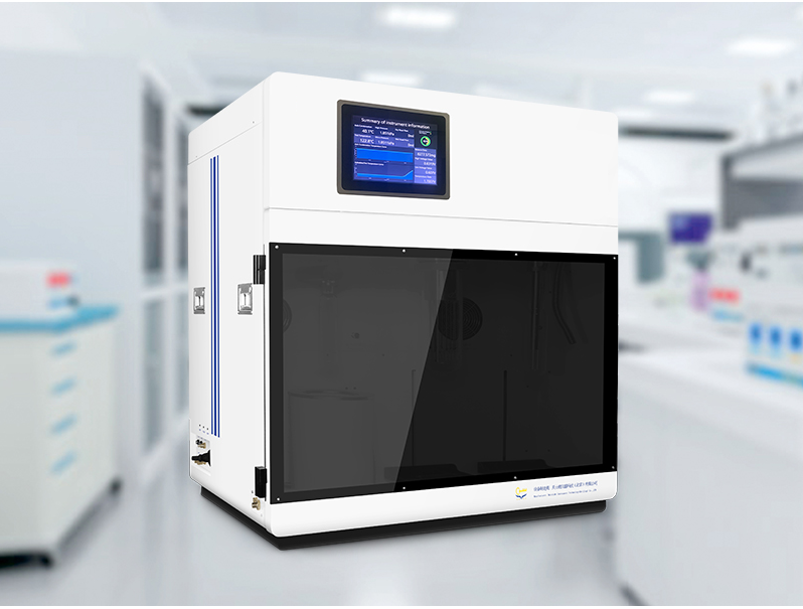

The STD-VTG analyzer is a research-grade instrument equipped with a molecular pump for high-vacuum analysis. When integrated with mass spectrometry as the VTG-MASS system, it represents the state-of-the-art in vacuum thermogravimetry.

Performance parameter

| Performance Category | Specifications |

|---|---|

| Test Function | Specialized vacuum thermogravimetric analysis (No atmospheric TGA support) |

| Programmable Temperature Range | 32-segment heating program; RT~900℃; Accuracy ±0.1℃, Stability ±0.1℃ |

| Micro-Weighing System | 1μg resolution; Max sample capacity 15g |

| Vacuum System | Dual-stage mechanical pump (ultimate vacuum <10⁻³ mbar); Optional turbo molecular pump (<10⁻⁶ mbar) |

| Analysis Stations | 2/4/8 stations for simultaneous multi-sample analysis |

| Blank Reference Testing | Multi-station analysis with blank reference positions; Automatic software background subtraction |

| MS Coupling Interface | High-vacuum large-bore interface for in-situ pyrolysis gas composition analysis |

◆Segmented Pressure Measurement:

Dual pressure sensors with split-range testing (0-1 torr / 0-1000 torr)

Original imported capacitive diaphragm sensors (≤0.15% precision error) - industry's highest accuracy

Segmented configuration significantly improves accuracy for adsorbates with low saturated vapor pressure at room temperature

◆ Original Imported Vacuum Pump:

German dual-stage directly-coupled pump (low noise, long lifespan)

Turbo molecular pump optional

◆ Quartz Wool Insulation Sealing:

High-standard quartz wool insulation for vacuum chamber sensors

Ultra-low leakage rate, aging-resistant, superior stability

◆ Intelligent Auto-Calibration:

Automatic leak detection protocol with smart system qualification

◆ Quadrupole Mass Spectrometer (Optional):

INFICON online mass spectrometer (Made in USA)

Provided with Certificate of Origin and Original Factory Calibration Certificate

Leave Message Get Price