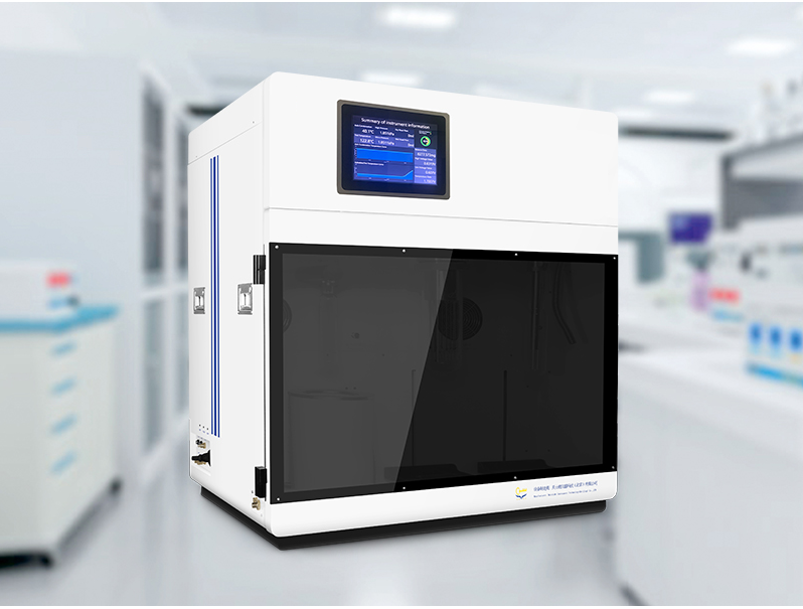

Specific Surface Area and Pore Size Analyzer(Static Volumetric Method)

Test Principle

At liquid nitrogen temperature (77.3K), a certain amount of adsorbate gas (N₂) is introduced into the sample tube. The adsorption partial pressure is directly measured by controlling the equilibrium pressure in the sample tube, and the adsorption amount at this partial pressure point is obtained using the gas equation of state PV=nRT. The specific surface area of the sample can then be calculated using theoretical formulas such as BET or Langmuir. By gradually adding adsorbate gas to increase the adsorption equilibrium pressure, the adsorption isotherm is obtained. By gradually removing adsorbate gas to decrease the adsorption equilibrium pressure, the desorption isotherm is obtained. Information such as pore size, pore volume, and pore size distribution of the sample can be calculated from the adsorption and desorption isotherm data.

Compared with the dynamic method, no carrier gas (He) is required, and there is no need to repeatedly raise and lower the liquid nitrogen cup. Since the sample to be tested is placed in a fixed-volume sample tube, the adsorbate does not flow, which is different from the dynamic chromatographic method, hence the name static volumetric method.

Note: 77.3K = -195.85°C

P: Pressure, V: Volume, n: Amount of substance, T: Temperature, R: 8.314 J•Mol⁻¹•K⁻¹

Technical Parameter

◆ Test functions: Evaluation of specific surface area, pore structure, and other gas adsorption properties

◆ Types of adsorbates: Testing of various non-corrosive gases

◆ Test range: Specific surface area above 0.0005 m²/g, pore diameter 0.35-500 nm

◆ Number of analysis stations: 1/2/4 analysis stations;

◆ Number of degassing stations: Optional 2/4 pretreatment stations;

◆ Independence: The testing system and degassing system are independent of each other, allowing simultaneous sample testing and degassing;

◆ Test accuracy: Specific surface area ≤±1.0%, most probable pore diameter repeatability deviation ≤0.15 nm, true density ≤±0.04%, external surface area ≤±1.5

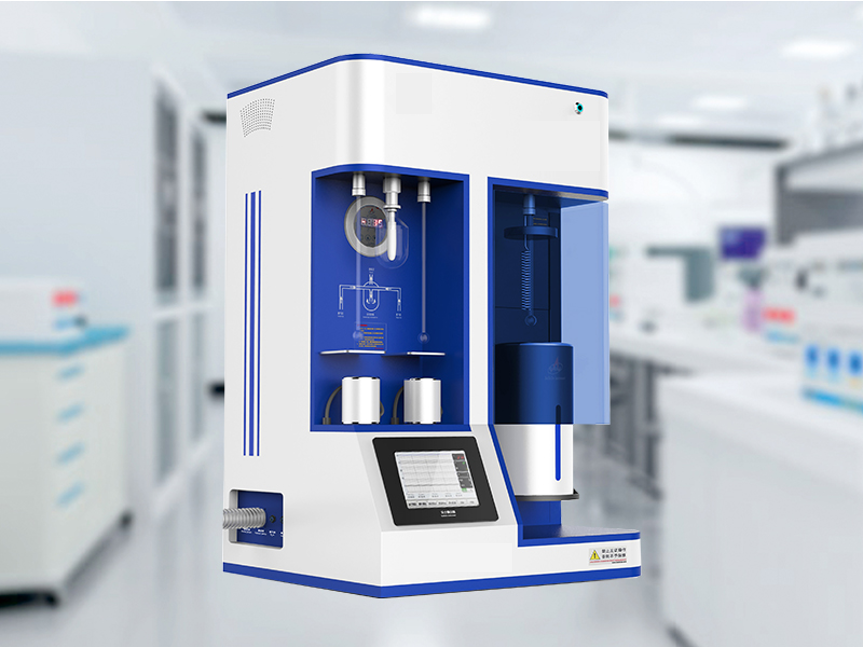

◆ Independent P0 station: Patented independent spiral saturated vapor pressure (P0) test station to ensure high accuracy of partial pressure testing

◆ Temperature-programmed degassing: Software-controlled temperature programming, room temperature-400°C, accuracy better than 0.1°C;

◆ Ultimate vacuum:

PS series: Original imported (Atlas Copco, formerly Edwards, UK) two-stage mechanical vacuum pump, vacuum degree 4*10-2 Pa,

PM series: 1 original imported turbomolecular pump from Edwards, Germany + 2 original imported mechanical pumps, P/P0 as low as 10-8;

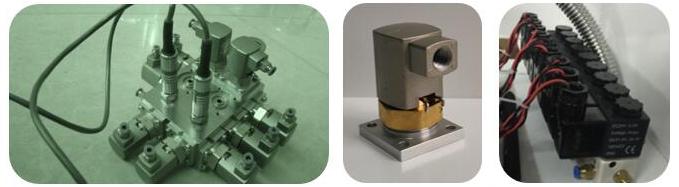

◆ Pressure measurement:

PS series: 1 original imported pressure sensor per test station, range 0-1000 torr

PM series: Multiple pressure sensors per test station, ranges 0-1 torr and 0-1000 Torr (0-0.1 Torr optional);

◆ Open data interface: The software can be integrated with LIMS to upload test results to LIMS.

Testing Report:

Leave Message Get Price