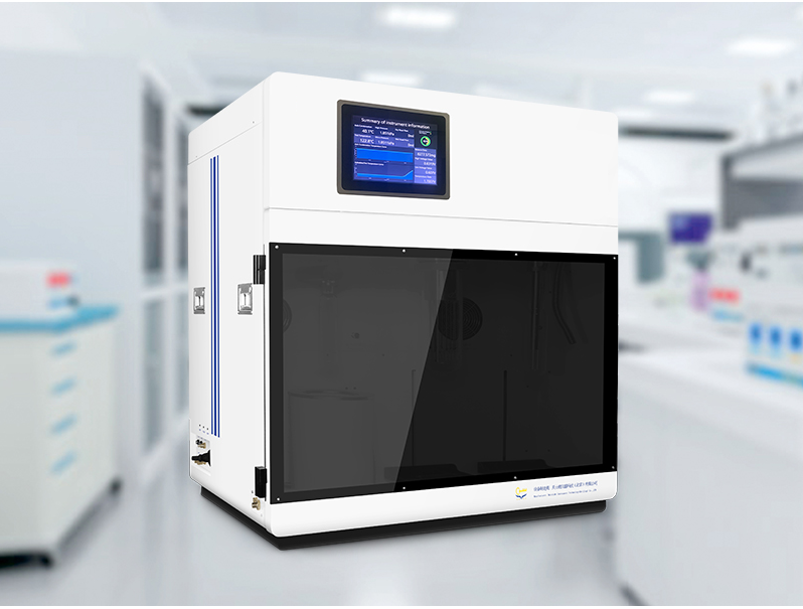

Vapor/Gas Sorption and Micropore Analyzer (Volume Method)

Selection Guide

| Model | Instrument Name | Main Functions | Hardware Differences | Test Temperature | Standard Configurations | Common Materials Tested |

| STD-660S | Specific Surface Area and Pore Size Analyzer | Adsorption analysis at liquid nitrogen temperature (77K), such as BET specific surface area analysis, mesopore volume and pore size analysis. | Oil pump, single-stage pressure sensor, solenoid valve, P/P0 limit better than E-5 | Standard: 3L Dewar cup, suitable for constant temperature such as liquid nitrogen 77K, liquid argon 87K, etc. | A3S, A6S, A3S|B3S, A6S|B6S | Non-porous materials, such as lithium battery materials, inorganic salts, oxides, hydroxides, metal powders, organic materials, etc. |

| STD-660M | Advanced Specific Surface Area and Micropore Analyzer | Includes functions of 660S, supports micropore analysis at 87K/Ar, 195K/CO2, etc., with micropore volume and pore size analysis capabilities. | Compared to 660S, equipped with molecular pump, multi-stage pressure sensor, gas-controlled diaphragm valve and other micropore configurations, P/P0 limit better than E-9 | Standard: 3L Dewar cup and constant temperature circulating bath, suitable for constant temperature from -10℃ to 80℃; Optional 1: Solid-liquid constant temperature bath cup, suitable for constant temperature such as ice water bath, ice salt bath, dry ice bath, etc.; Optional 2: BSD-LNT ultra-low temperature constant temperature device, suitable for constant temperature from 110K to 273K | A3M, A6M, A6S|B3M, A6S|B6M, A3M|B3M, A6M|B6M | Porous materials, such as zeolite molecular sieves, activated carbon, MOF, COF, HOF, porous carbon, silica gel, etc. |

| STD-660MG | Advanced Gas Adsorption and Micropore Analyzer | Includes functions of 660M, adapts to fully automatic continuous adsorption analysis and fully automatic cycle adsorption life evaluation at multiple gas types and multiple temperature points; various non-corrosive gas adsorption, such as N2, CO2, H2, CO, C1~C4 hydrocarbon gases, etc. | Compared to 660M, equipped with automatic multi-channel intake module and constant temperature bath communication function, multi-channel gas automatic switching, automatic flushing, automatic adsorption temperature switching. | - | A3MG, A6MG, A6S|B3MG, A3MG|B3MG, A6MG|B6MG | - |

| STD-660MC | Advanced Corrosive Gas Adsorption and Micropore Analyzer | Includes functions of 660MG, with NH3, SO2, BF3 and other corrosive gas adsorption analysis capabilities. | Compared to 660MG, pipelines, valves, pressure sensors, sealing materials, etc., have stronger corrosion resistance, and equipped with corrosive adsorbate enrichment devices. | - | A3MC, A6MC, A3MG|B3MC | - |

| STD-660MV | Vapor/Gas Sorption and Micropore Analyzer (Volume Method) | Includes functions of 660MG, with water vapor, organic vapor adsorption analysis capabilities. | Compared to 660MG, a vapor adsorption module is added, and a vapor enrichment device is added to reduce the contamination of the pump oil by the vapor. |

Main Function

◆ Vapor Sorption: Such as H2O, organic vapors, etc.;

◆ Conventional Gas Adsorption: Such as N2, O2, Ar, CO, CO2;

◆ Combustible Gas Adsorption: Such as H2, CH4, C2H6, and other alkanes and alkynes;

◆ Full Functionality: Specific surface area, mesopore, micropore, and supermicropore analysis;

◆ High Throughput: Analysis station quantity selectable from 3/6/9/12;

◆ Fully Automatic: Degassing → testing, fully automatic switching;

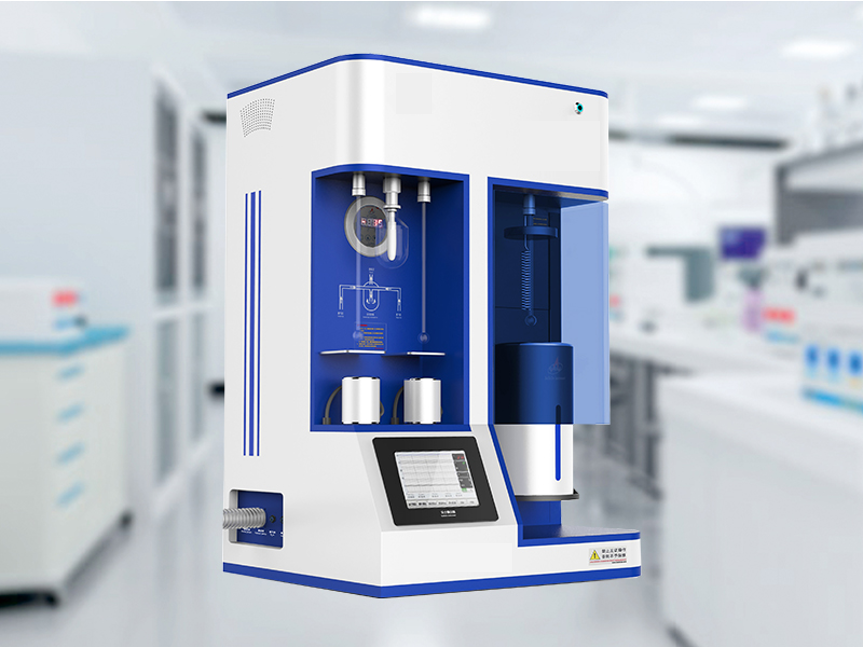

◆ High Configuration: Optional dual-station dual molecular pump system, molecular pump degassing;

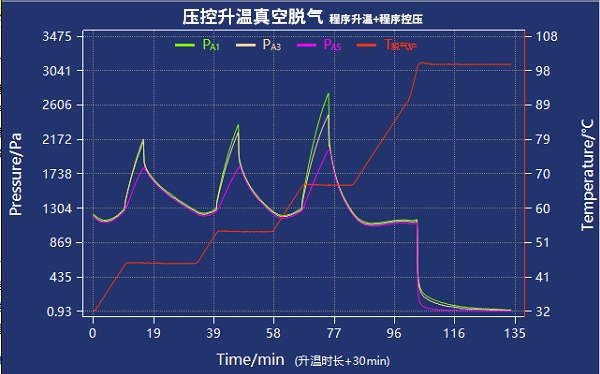

◆ Anti-contamination: "Pressure-controlled heating" anti-contamination degassing for microporous samples;

◆ Zero Helium Contamination: Helium gas temperature measurement zone first, followed by automatic degassing;

◆ Automatic Cycling: Automatic evaluation of material cyclic adsorption performance.

Technical Parameter

Here is the translation of the additional content you provided:

◆ Broad Testing Range: Specific surface area above 0.0005 m²/g, pore size 0.35-500 nm;

◆ Testing Efficiency: Multi-point BET (excluding degassing process), standard mode 12 samples/60 min; rapid testing mode 12 samples/15 min;

◆ High Testing Accuracy: Specific surface area, pore size, pore volume, adsorption capacity, with a quantitative error < 0.5% RSD (based on standard sample BET value);

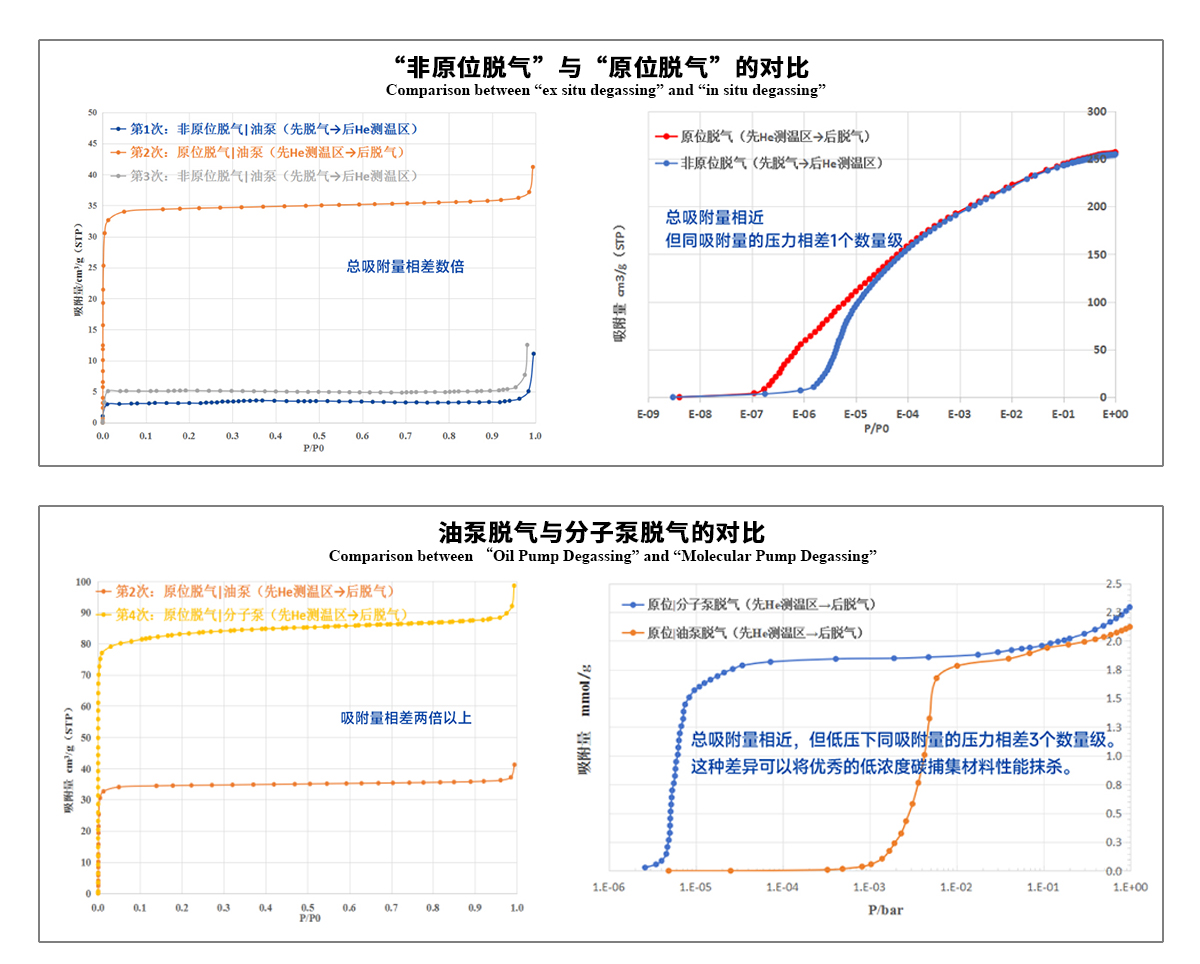

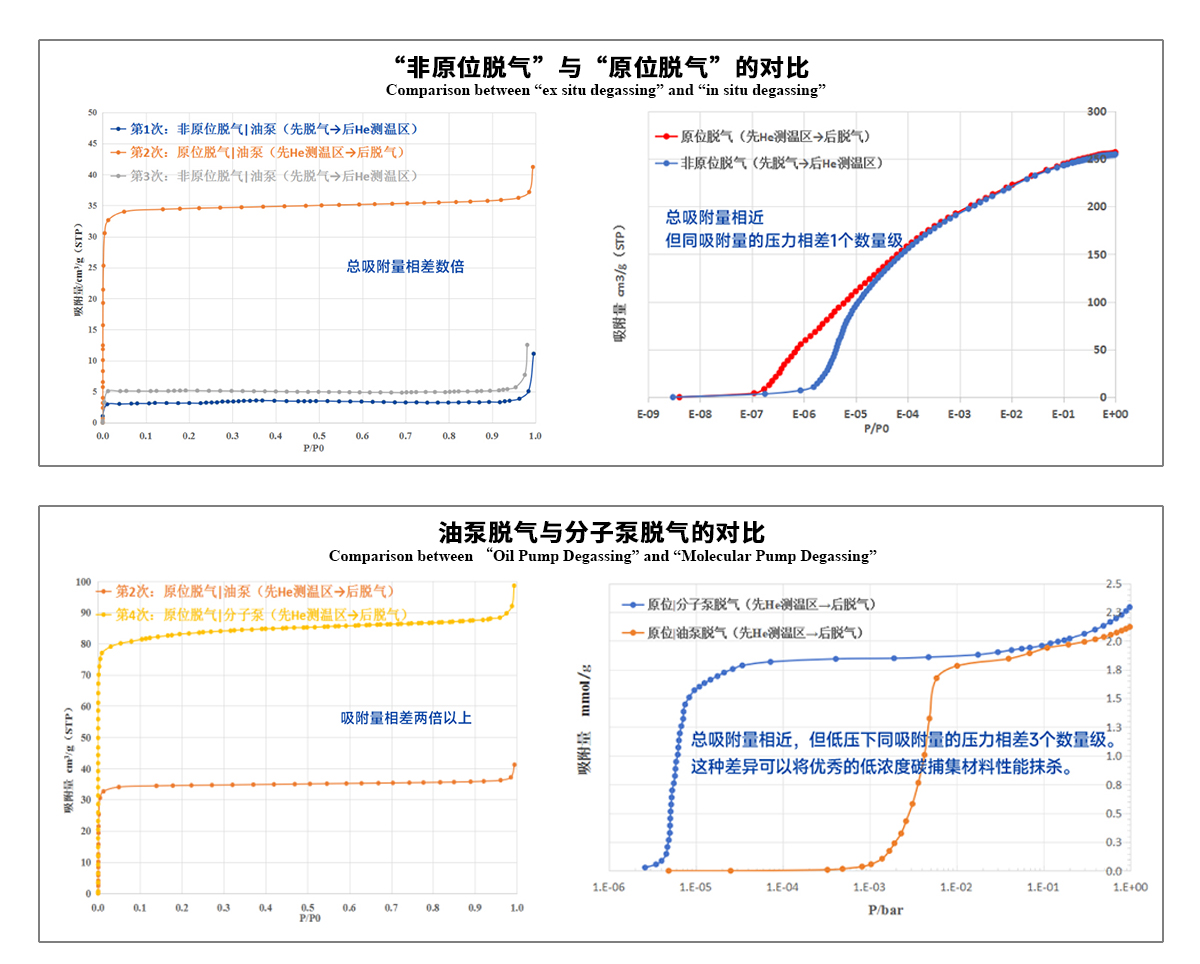

◆ Molecular Pump Degassing: Standard in-situ vacuum molecular pump degassing, which improves vacuum level by 2-3 orders of magnitude compared to oil pump degassing;

◆ Intelligent Degassing Completion Judgment: Supports software automatic judgment, automatically judging degassing effect based on pressure changes;

◆ Anti-flying Degassing: Pressure-controlled heating + pressure-controlled vacuum pumping, a dual approach to completely eliminate sample flying during degassing;

◆ Vacuum Level: Vacuum level up to 10⁻⁸ Pa.

Technical advantages

Here is the translation of the additional content you provided:

◆ High Throughput and High Efficiency

Supports analysis of up to 12 samples at once;

◆ True Full Automation

Internationally pioneering automatic switching between degassing furnace and Dewar cup, eliminating the need for manual transfer of sample tubes or degassing furnace;

◆ High Time Utilization

Resolves the time wastage issue of conventional instruments where degassing completes after work hours, preventing the initiation of testing, making it possible to load samples after work and view data the next working day;

◆ Complete Elimination of 'Helium Contamination'

Helium gas test dead volume → vacuum heating degassing → adsorption testing, pioneering the resolution of the helium contamination challenge in micropore analysis within the international scope, enhancing testing accuracy;

◆ Anti-flying Degassing

Supports 'pressure-controlled heating' + 'pressure-controlled vacuum pumping', automatically adjusting programmed heating and vacuum pumping rates based on pressure changes to prevent sample flying;

◆ Supports Automatic Cycling Testing

Automatic degassing + testing cycling for evaluating material adsorption performance stability and adsorption performance lifetime assessment;

◆ 'Pressure-controlled Heating' Sample Pore Protection Technology (Compliant with International Standard ISO 9277:2022)

Programmed heating technology under gas pressure control, automatically starting and stopping programmed heating based on pressure changes to prevent excessively rapid gas release from samples, thereby preventing sample pore damage caused by rapid gas release; (This phenomenon is more common with microporous samples. Once sample pore damage occurs, it is difficult to detect and is one of the important sources of instability in microporous sample test results).

Comparative Testing

Data Report

Leave Message Get Price