Specific Surface Area and Pore Size Analyzer

Selection

| Instrument Model | Instrument Name | Main Functions |

| STD-660S | Specific Surface Area and Pore Size Analyzer | Adsorption analysis at liquid nitrogen temperature 77K, such as BET specific surface area analysis, meso-pore volume and pore size analysis. |

| STD-660M | Advanced Specific Surface Area and Micropore Analyzer | Including functions of 660S, supports micropore analysis at 87K/Ar, 195K/CO2. etc., with micropore volume and pore size analysis capabilities. |

| STD-660MG | Advanced Gas Adsorption and Micropore Analyzer | Including functions of 660M, fully automatic continuous adsorption analysis for various gases and multiple temperature points, and fully automatic cycle adsorption lifetime evaluation. |

| STD-660MC | Advanced Corrosive Gas Adsorption and Micropore Analyzer | Including functions of 660MG, with adsorption analysis capabilities for corrosive gases such as NH3. SO2. BF3. |

| STD-660MV | Vapor/Gas Sorption and Micropore Analyzer (Volume Method) | Including functions of 660MG, with adsorption analysis capabilities for water vapor and organic vapors. |

| Hardware Differences | Test Temperatures | Routine Configurations (Number of Analysis Positions) | Commonly Tested Materials |

| Oil pump, single-stage pressure sensor, solenoid valve, P/P0 lower limit better than E-5 | Standard: 3L Dewar flask, liquid nitrogen 77K, liquid argon 87K | A3S, A6S, A3S|B3S, A6S|B6S | Non-porous materials such as lithium battery materials, inorganic salts, oxides, hydroxides, metal powders, organic materials |

| Compared to 660S, configured with molecular pump, multi-stage pressure sensor, gas-controlled diaphragm valve and other micropore configurations, P/P0 lower limit better than E-9 | Standard: 3L Dewar flask, constant temperature circulating bath, -10℃~80℃ | A3M, A6M, A6S|B3M, A6S|B6M, A3M|B3M, A6M|B6M | Porous materials such as zeolite molecular sieves, activated carbon, MOF, COF, HOF, porous carbon, silica gel |

| Compared to 660M, configured with automatic multi-channel intake module and constant temperature bath communication function, multi-channel gas automatic switching, automatic flushing, automatic adsorption temperature switching. | Same as above | A3MG, A6MG, A6S|B3MG, A3MG|B3MG, A6MG|B6MG | - |

| Compared to 660MG, pipelines, valves, pressure sensors, sealing materials, etc., have stronger corrosion resistance, and equipped with corrosive adsorbate enrichment device. | Same as above | A3MC, A6MC, A3MG|B3MC | - |

| Compared to 660MG, a vapor adsorption module is added, equipped with a vapor enrichment device to reduce vapor contamination of pump oil. | Same as above | A3MV, A6MV, A3MG|B3MV, A3MC|B3MV |

Main Function

◆ Full-functional: Specific surface area, mesopore, and micropore analysis;

◆ High-throughput: Optional analysis stations (3/6/9/12);

◆ Fully automatic: Degassing → Testing, fully automatic switching;

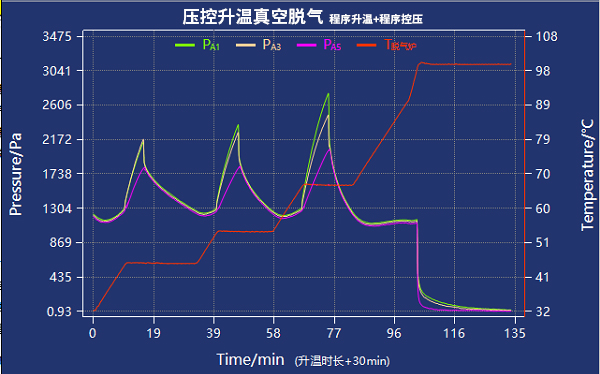

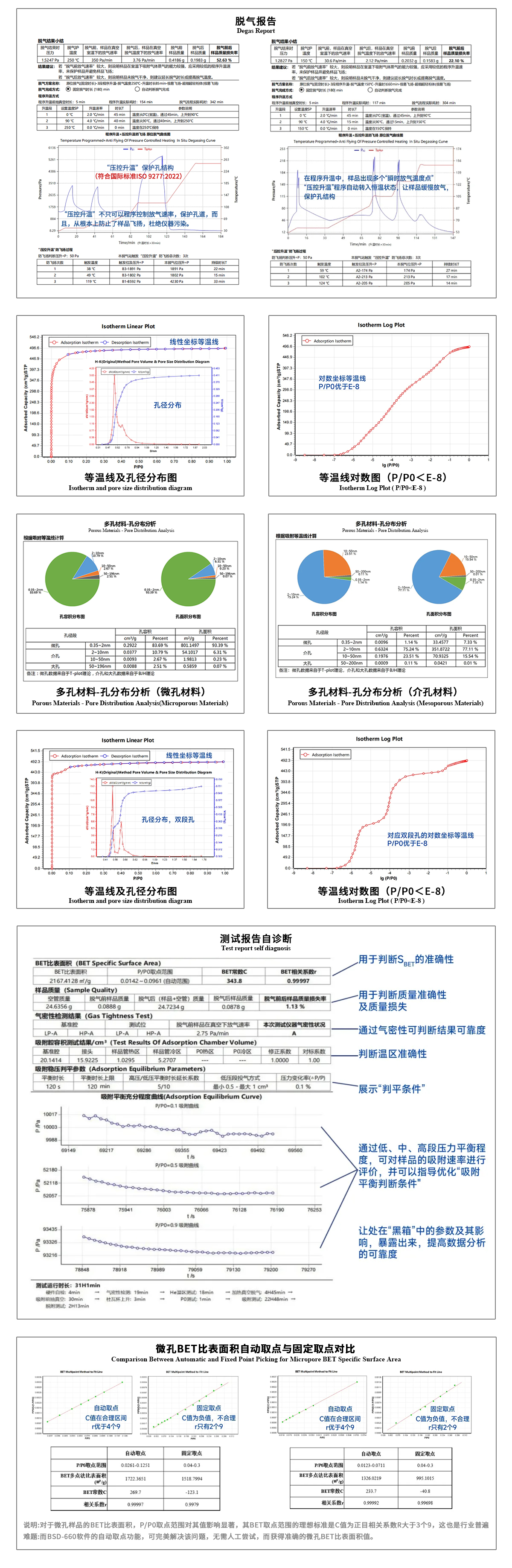

◆ Anti-contamination: "Pressure-controlled heating" for micropore sample degassing to prevent contamination;

◆ Zero helium contamination: Pre-heating zone with helium gas, followed by automatic degassing;

◆ Auto-cycling: Automatic evaluation of material cyclic adsorption performance.

Technical Parameter◆ Broad testing range: Specific surface area ≥0.0005 m²/g, pore size 0.35-500 nm;

◆ Testing efficiency: Multi-point BET (excluding degassing process), standard mode 12 samples/60 min; rapid testing mode 12 samples/15 min;

◆ High testing accuracy: Quantitative error of specific surface area, pore size, pore volume, and adsorption capacity <0.5% RSD (based on standard sample BET value);

◆ Temperature-programmed degassing: Software-controlled temperature programming, room temperature to 400°C, accuracy better than 0.1°C;

◆ Intelligent degassing completion judgment: Software-supported automatic judgment based on pressure changes to evaluate degassing effectiveness;

◆ Anti-dust degassing: Pressure-controlled heating + pressure-controlled vacuuming to completely eliminate sample dusting during degassing;

◆ Vacuum level: 10⁻² Pa;

◆ High reliability: International supplier system, core components imported with original packaging.

Technical Parameter

◆ Wide Test Range: Specific surface area above 0.0005 m²/g, pore size 0.35-500 nm.

◆ Testing Efficiency: Multi-point BET (excluding degassing process), standard mode 12 samples/60 min; rapid test mode 12 samples/15 min.

◆ High Testing Accuracy: Quantitative error of specific surface area, pore size, pore volume, and adsorption capacity is less than 0.5% RSD (based on the BET value of standard samples).

◆ Temperature-programmed Degassing: Software-controlled temperature programming, room temperature to 400℃, accuracy better than 0.1℃.

◆ Intelligent Degassing Completion Judgment: Supports automatic software judgment, automatically judges the degassing effect based on pressure changes.

◆ Anti-飞扬 Degassing: Pressure-controlled heating + pressure-controlled vacuum pumping, a two-pronged approach to completely solve the phenomenon of sample 飞扬 during the degassing process.

◆ Vacuum Degree: 10-2 Pa.

◆ High Reliability: International supplier system, core components are all imported.

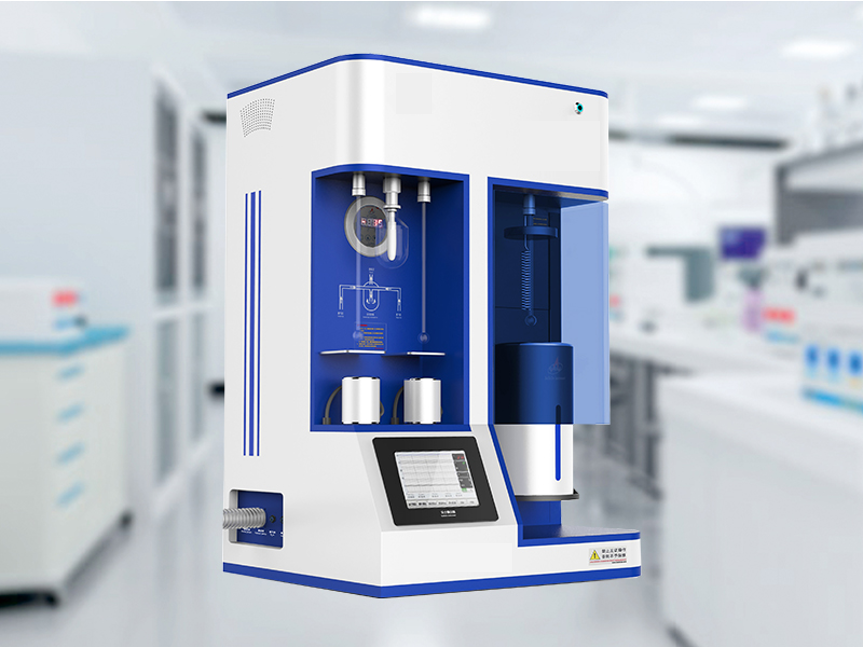

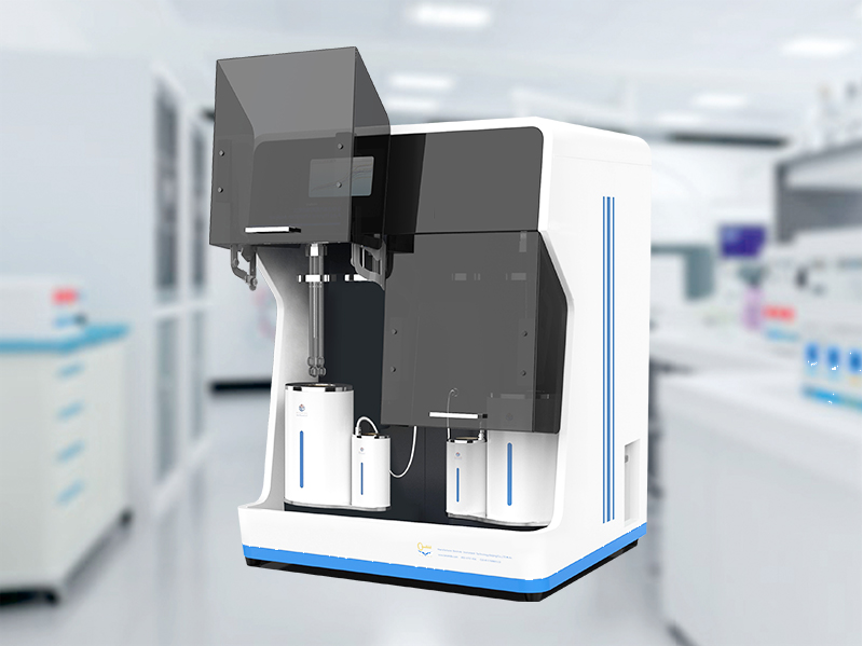

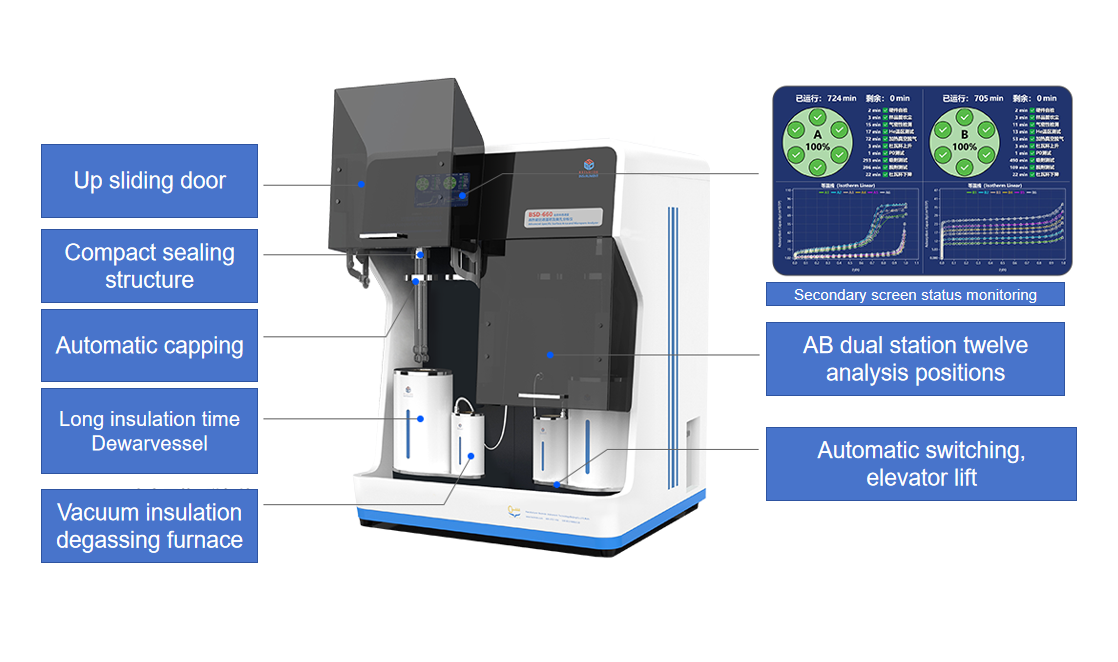

Characteristic Structure

Technical Advantages

◆ High-throughput and high-efficiency

Supports analysis of up to 12 samples at once;

◆ Truly fully automated

International first: automatic switching between degassing furnace and Dewar cup, no manual transfer of sample tubes or degassing furnace required;

◆ High time utilization

Solves the time waste issue of conventional instruments where degassing is completed after work hours, but testing cannot start. Enables sample loading after work and data viewing the next day;

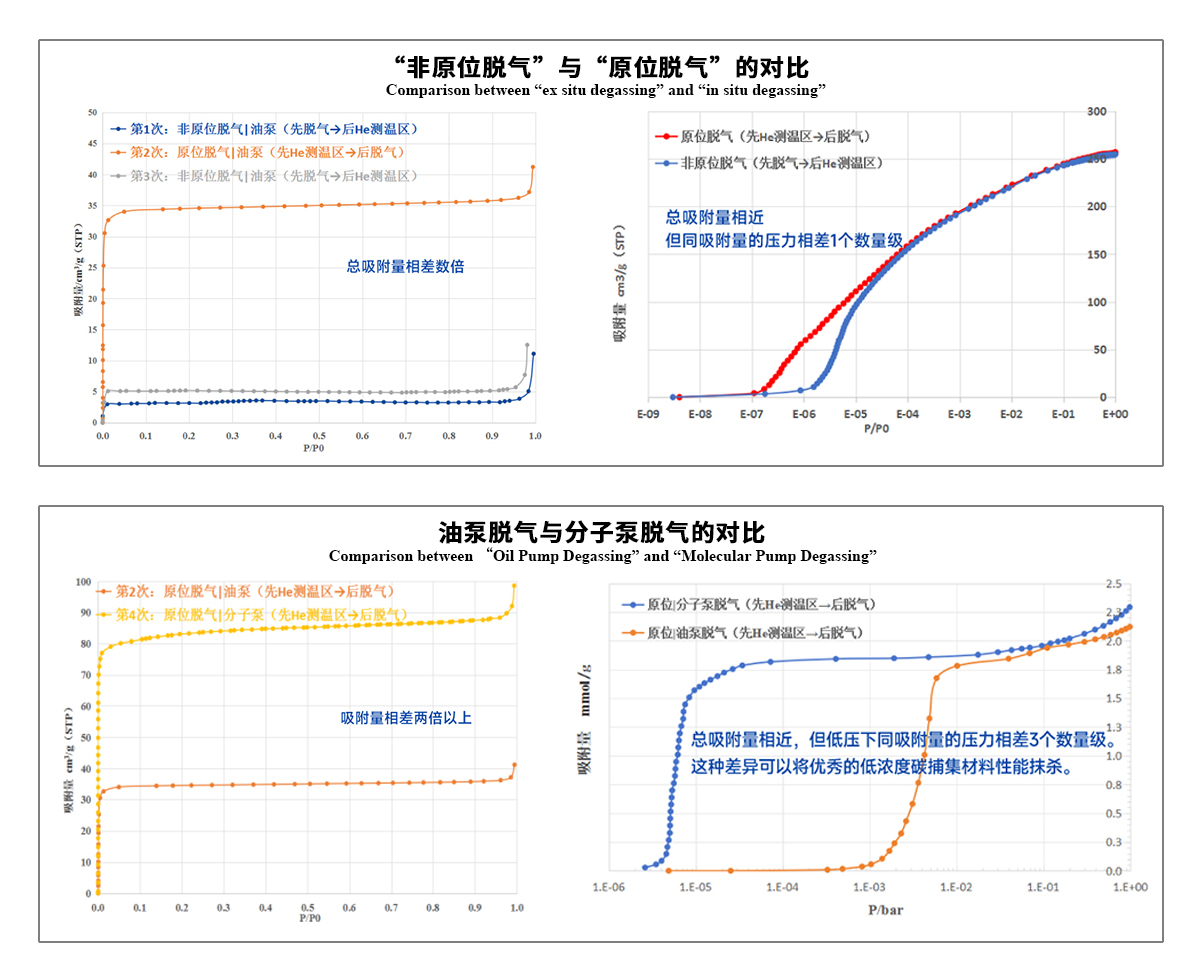

◆ Complete elimination of "helium contamination"

Pioneering solution in the international arena: helium gas dead volume test → vacuum heating degassing → adsorption test, improving test accuracy by addressing the helium contamination challenge in micropore analysis;

◆ Anti-dust degassing

Supports "pressure-controlled heating" + "pressure-controlled vacuuming", automatically adjusting temperature programming and vacuuming rate based on pressure changes to prevent sample dusting;

◆ Supports automatic cycle testing

Automatic degassing + testing cycle for evaluating material adsorption performance stability and adsorption lifespan;

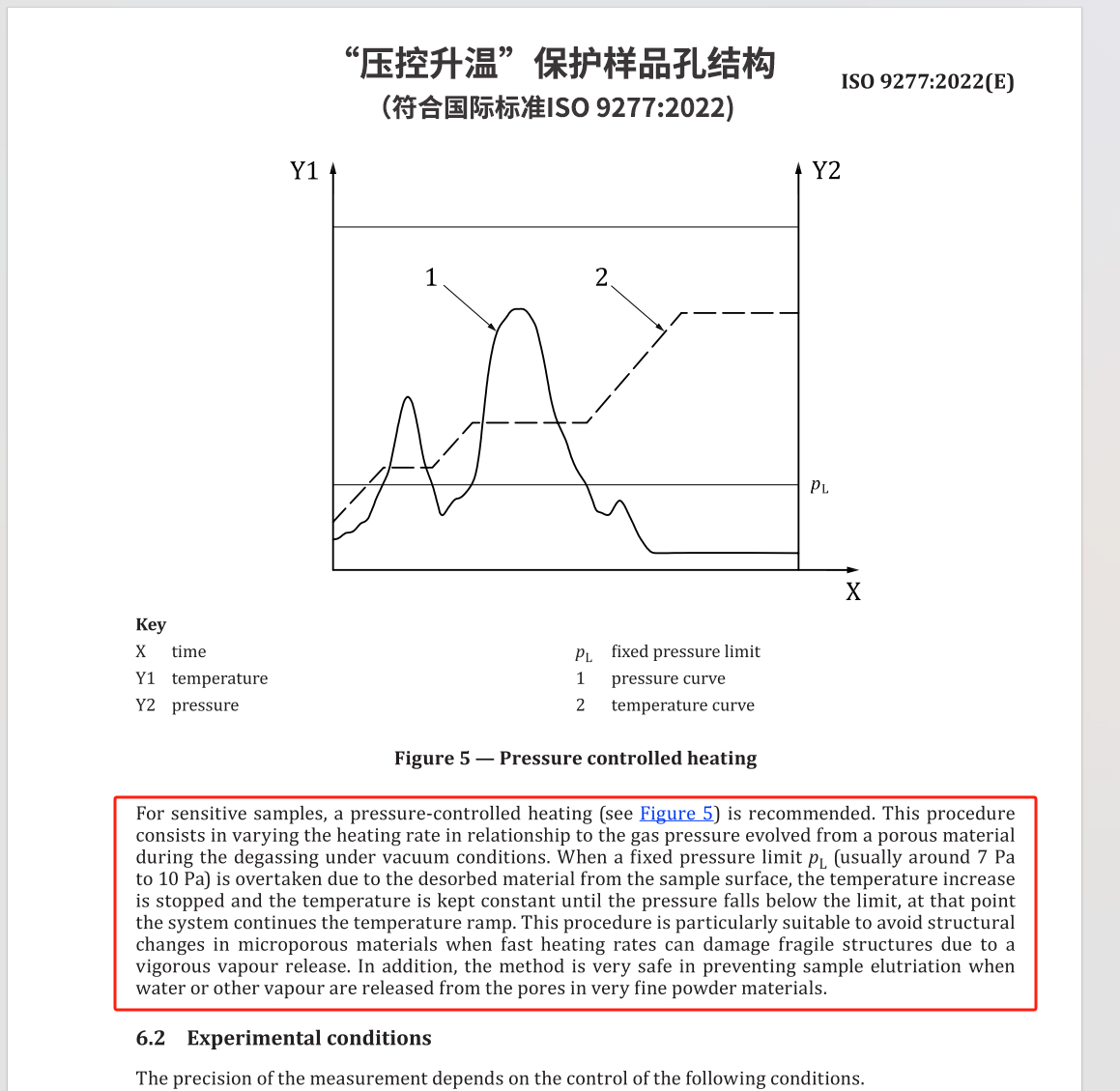

◆ "Pressure-controlled heating" sample pore protection technology (compliant with international standard ISO 9277:2022)

A temperature programming technique under gas pressure control, automatically starting and stopping temperature programming based on pressure changes to prevent excessive gas release and damage to sample pores (a common issue with micropore samples. Once pore damage occurs, it is difficult to detect and is a major source of instability in micropore sample test results).

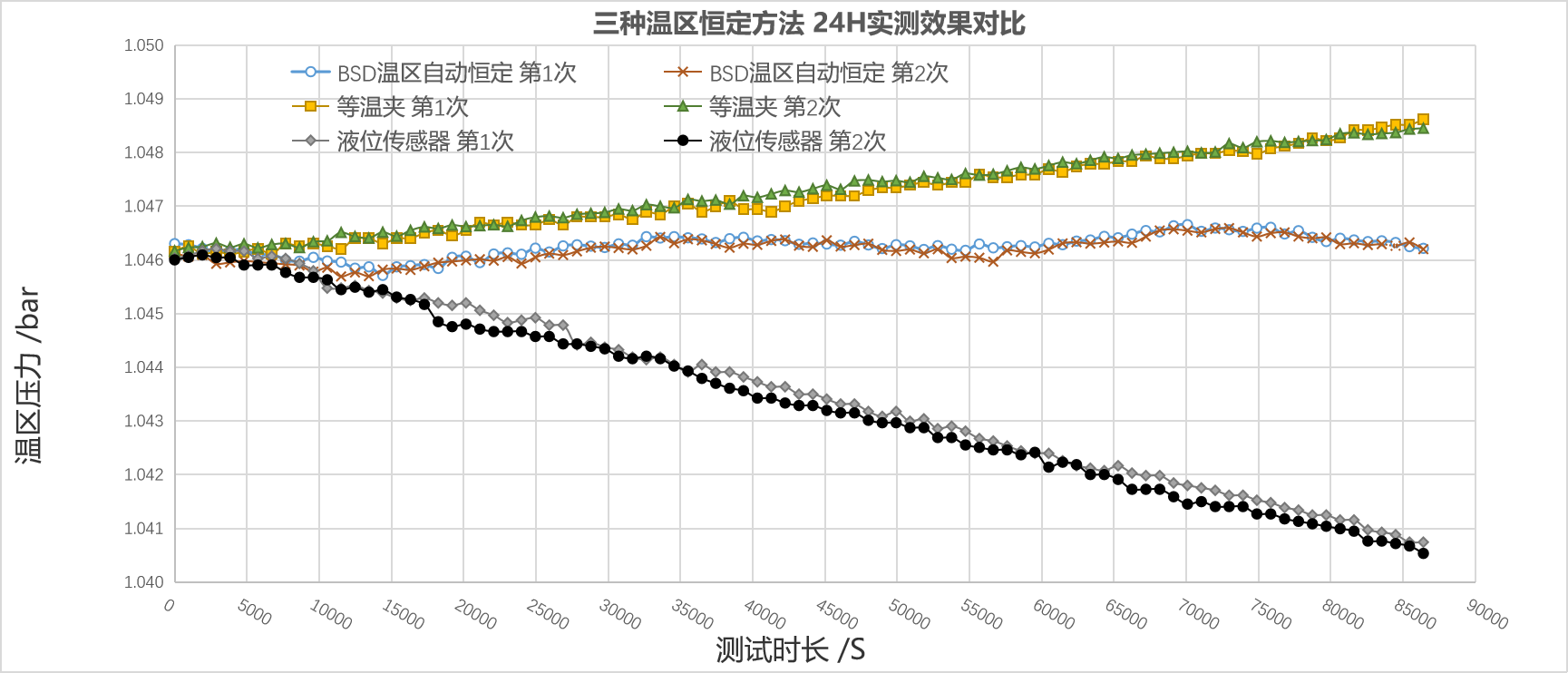

◆ "Automatic constant temperature zone" patented technology

The curve shows that the 24-hour change rates of the "adsorption chamber equivalent volume" under three constant temperature zone methods are: BSD temperature zone servo automatic constant: 0.10%, isothermal clamp: 0.25%, liquid level sensor: 0.55%

◆ Convenient installation and sealing

Single analysis station with one-time sealing technology for 6 sample tubes, no need to seal each tube individually, providing unparalleled efficiency;

◆ Fully constant temperature gas path system

The internal gas path system of the instrument is fully constant temperature up to 40°C, with accuracy better than ±0.01°C;

◆ Upward-opening door

Humanized and easy to open and close, saving laboratory space;

◆ Electric turbo liquid nitrogen pump

Humanized liquid nitrogen addition, stepless speed regulation, free movement, safe and convenient, no liquid nitrogen contamination;

◆ Open data interface

The software can be integrated with LIMS to upload test results to LIMS.

Comparative Testing

Data Report

Leave Message Get Price