Automatic True Density Analyzer

Test function

◆ True density testing (powders, granules, blocks, flakes, liquids, slurries, etc.)

◆ Porosity (open porosity, closed porosity) (bulk materials, foam materials, cores, metal components, etc.)

Test principle

◆ Applying Archimedes' principle - gas expansion displacement method, using the Boyle's Law (PV=nRT) of inert gases with small molecular diameters under certain conditions, the true density of the sample is accurately determined by measuring the volume of gas displaced by the sample in the test chamber to precisely determine the skeleton volume of the sample (including closed pores), so the true density is obtained as mass divided by skeleton volume.

◆ The gas expansion displacement method replaces the liquid with gas to measure the volume displaced by the sample. This method avoids the test error caused by sample dissolution in the immersion method and has the advantage of not damaging the sample. Because gas can penetrate into the tiny pores and irregular surface pores of the sample, the measured sample volume is closer to the skeleton volume of the sample, which can be used to calculate the density of the sample, and the test value is also closer to the true density of the sample.

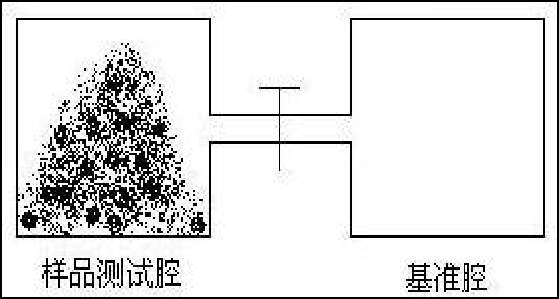

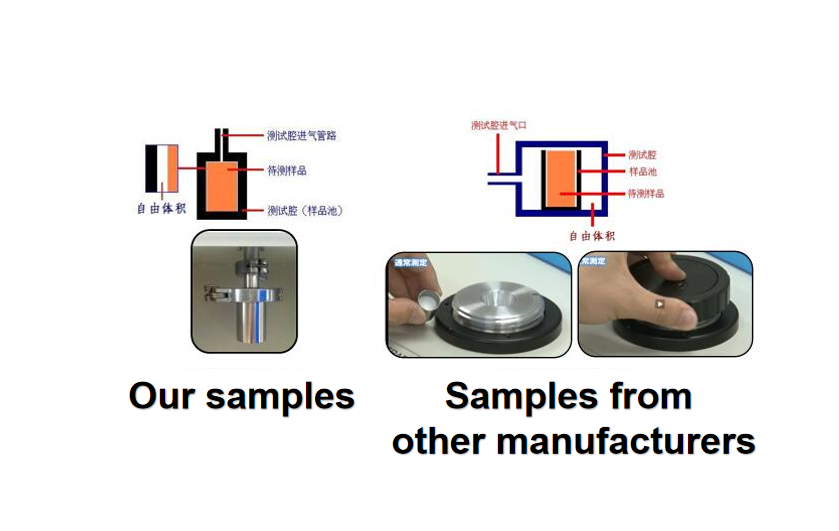

◆ The test system of the instrument consists of a test chamber and a reference chamber, as shown in the figure.

Instrument standard

| Standard Abbreviation | English Translation |

|---|---|

| GB/T 40401-2021 | Measurement of Skeletal Density - Gas Volume Displacement Method |

| GB/T10799-2008 | Rigid Cellular Plastics - Determination of Percentage of Open and Closed Cell Volumes |

| GBT 5071-2013 | Refractory Materials - True Density Test Method |

| ASTM D2856 | Standard Test Method for Open Cell Content of Rigid Cellular Plastics Using an Air Pycnometer |

| ASTM D6226-2005 | Test Method for Open Cell Content of Rigid Microcellular Plastics |

| MT/T713-1997 | Method for True Density Determination of Coal Mine Dust |

Technical parameter

◆ Test Content: True density, open and closed porosity

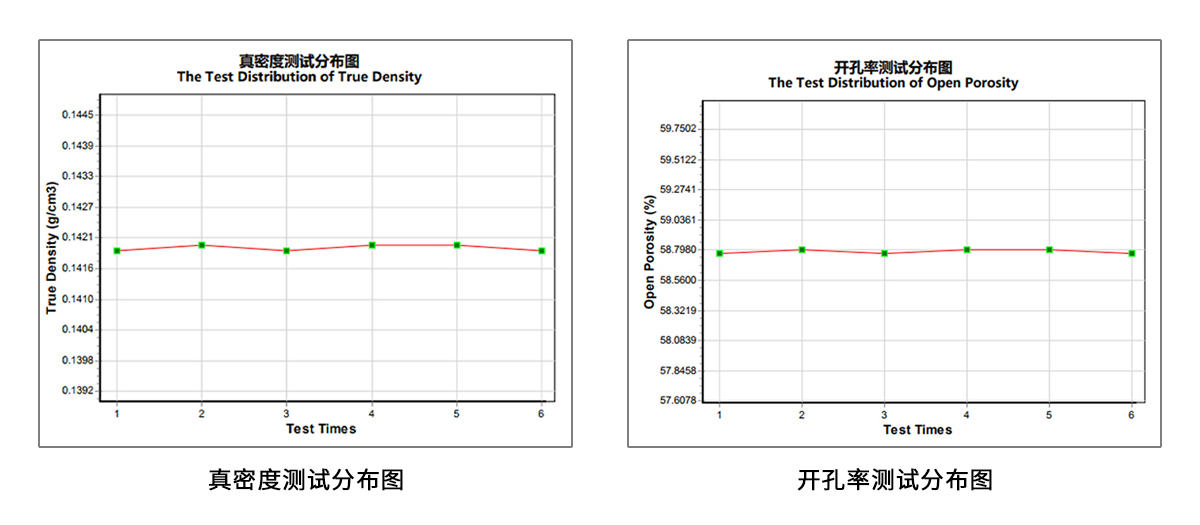

◆ Test Accuracy: Precision better than ±0.03%, repeatability better than ±0.015%, resolution: 0.0001g/ml;

◆ Test Speed: Single station completes the entire test process in 0.5-1min, double station analysis efficiency is doubled;

◆ Number of Analysis Stations: 1-2 stations;

◆ Applicable Scope: Sample density size is not limited, can measure various solid samples such as powders, granules, blocks, foams, as well as slurry substances, non-volatile liquids and other samples

◆ Test Method: The sample cell is directly used as the sample test chamber, which has the advantage of high utilization rate of the sample test chamber volume compared with similar instruments, thereby improving the test accuracy; the "lower-mounted bayonet-type" sample cell can meet the needs of large-volume sample loading to achieve the purpose of improving test accuracy

◆ Constant Temperature Mode: Fully automatic programmed constant temperature mode, constant temperature accuracy error <0.1℃; programmed control of the constant temperature process, and automatically enter the test process

◆ Inner Square Sample Cell: Dedicated for open and closed porosity testing, which can reduce errors for bulk samples

◆ Reference Chamber: Equipped with 1 built-in reference chamber and 1 expansion chamber; the expansion chamber can improve test accuracy for different sample cell volumes; the program automatically selects whether to enable the expansion chamber based on the sample cell volume

Technical advantages

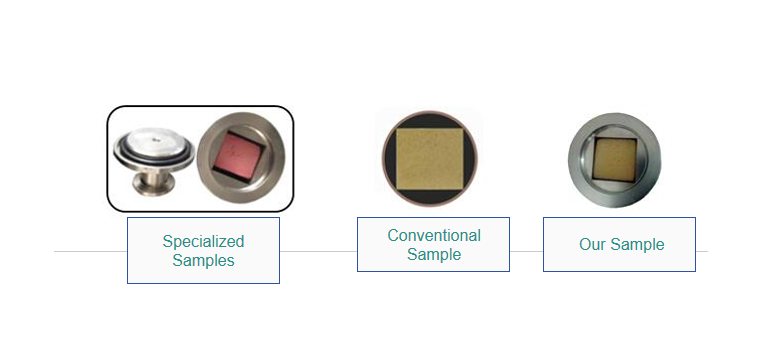

Designed based on the requirements of the national standard GBT 10799-2008 for the determination of open and closed cell volume percentages of rigid cellular plastics, the specialized sample cell for open and closed porosity testing is introduced.

◆ Conventional Sample Cell: Cylindrical sample cells are suitable for cylindrical samples. When using cubic samples, there will be a large amount of empty space, resulting in a sample cell volume utilization rate of less than 50%, which has a significant impact on open and closed porosity testing.

◆ Our Sample Cell: Rectangular sample cells are suitable for rectangular samples, with a sample cell volume utilization rate exceeding 80%, which is more beneficial for open and closed porosity testing. The stainless steel metal sample cell is durable and long-lasting.

◆ National Standard: The test for open and closed cell volume percentages of rigid cellular plastics GBT 10799-2008 has the following requirements for sample sizes:

Two regular cylinders with a cross-sectional area of 6.25cm² and a height of 2.5cm (optional size)

Two regular cubes with dimensions of 2.5cm2.5cm2.5cm (recommended size by the national standard)

◆ Regular cubes are relatively easy to cut with ordinary tools, and measuring their external volume is simple.

◆ Regular cylinders are extremely difficult to cut unless using specialized cutting tools, and measuring their external volume is very inconvenient.

◆ Using the test chamber directly as the sample cell results in very little free volume, effectively utilizing the test chamber space and being more beneficial for testing foaming materials with high open porosity.

◆ When the sample cell is placed inside the test chamber for testing, there is a lot of free volume, requiring the use of standard materials such as aluminum blocks or steel balls to fill the free volume. The space utilization rate of the test chamber can only reach 50%, making it unsuitable for testing foaming materials with high open porosity.

◆ Pneumatic Control Valve (Japan SMC)

The opening and closing of the valve is controlled by gas, so there is no heating problem. It will not cause gas expansion due to temperature changes, ensuring the stability and accuracy of the test results.

◆ Solenoid Valve

The opening and closing of the valve is controlled by the electromagnetic coil being energized. When the valve is working, there is an instantaneous heating problem, which causes the gas in the gas path to expand, seriously affecting the stability and accuracy of the test results.

◆ Comparison between Pneumatic Control Valve and Solenoid Valve

The pneumatic control valve is driven by gas to push the cylinder to drive the valve core to achieve the opening and closing of the valve, so there is no heating and the valve temperature is stable.

The solenoid valve is driven by a magnetic field generated by an electric current to drive the valve core to achieve the opening and closing of the valve. The electromagnetic coil heats up, and the valve temperature increases with the duration of energization. Even a temperature increase of 1℃ will cause an error in the quantitative gas volume of about 0.3%, which is far greater than the repeatability error requirement of 0.02%.

Data report

Leave Message Get Price