Bubble Pressure Method Membrane Pore Size Analyzer

Test Principle Main Function

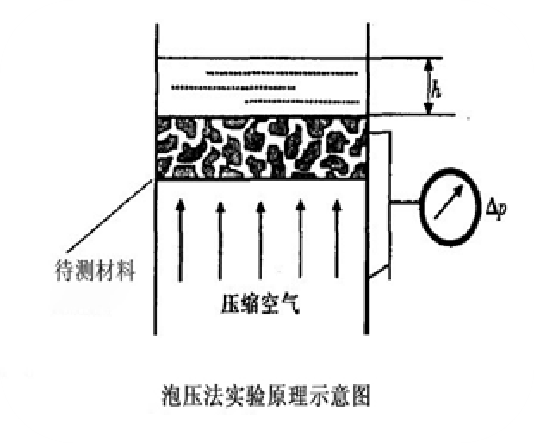

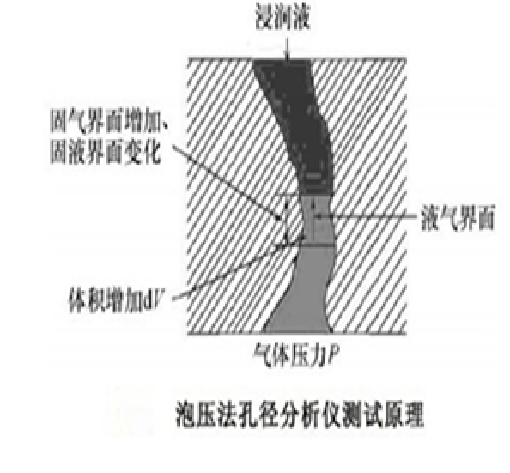

Gas-Liquid Displacement (Bubble Point Method):

A pressure difference is applied across the membrane to overcome the surface tension of the wetting liquid within the membrane pores, driving the wetting liquid through the pores. This method is used to obtain pore throat size data for porous membrane materials. It is also a standard method for thin film measurement as per ASTM standards.

Example:

Taking a certain membrane material as an example, the membrane is fully wetted with a liquid that can wet it. Due to surface tension, the wetting liquid is trapped within the membrane's pores. When a gradually increasing gas pressure is applied to one side of the membrane, the wetting liquid in a pore is displaced by gas when the gas pressure exceeds the capillary pressure exerted by the wetting liquid in that pore. Since smaller pore sizes result in higher capillary pressures, a higher gas pressure is required to displace the wetting liquid. Therefore, the wetting liquid in the largest pores is displaced first, allowing gas to pass through. As the pressure increases, the wetting liquid in the pores is displaced in order from largest to smallest, until all pores are opened, achieving the same permeability as a dry membrane.

Liquid-Liquid Displacement Method:

After wetting the filter material to be tested with a completely wetting liquid, an immiscible liquid is used as the displacing liquid to displace the wetting liquid from the through pores. Pore size data of the filter material can be obtained using the Washburn equation based on liquid flow rate and pressure data. Since the interfacial tension between two liquids is much smaller than that between gas and liquid, the liquid-liquid displacement method can test filter materials with smaller pore sizes compared to the gas-liquid displacement method (bubble point method).

Relationship between pore size and pressure (Washburn equation):

D = 4γcosθ / p

Where: D = pore diameter, γ = liquid surface tension, θ = contact angle, p = pressure difference.

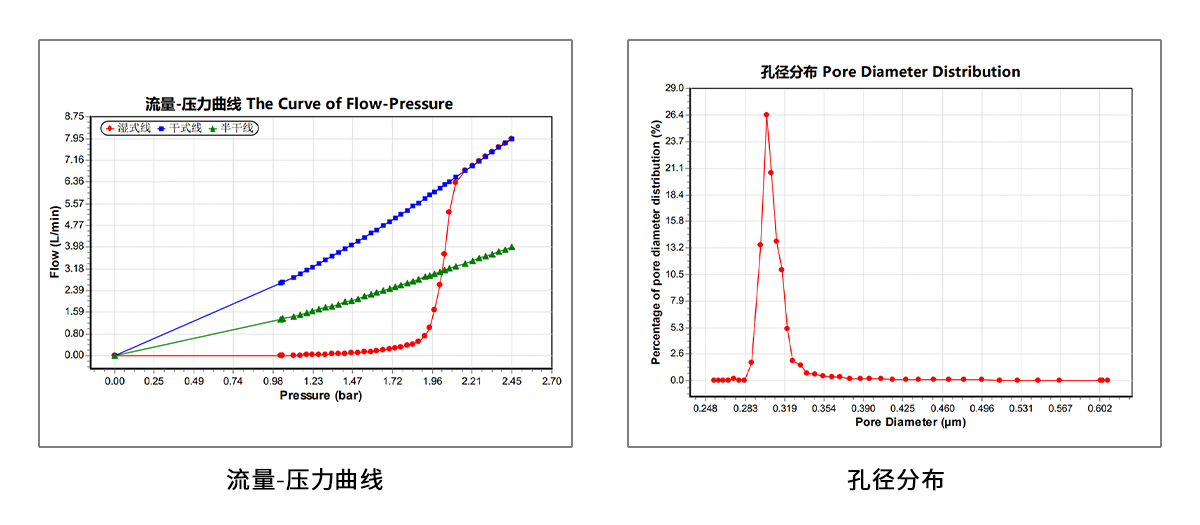

Flow percentage of pore size distribution:

f(D) = -d[(Fw/Fd) × 100] / dD

Where: Fw = wet sample flow rate, Fd = dry sample flow rate.

Scope of application

Pore throat testing for materials such as filter membranes, fibrous membranes, filter cartridges, battery separators, fabrics, nonwovens, paper, ceramics, sintered metals, rocks, concrete, etc., as well as lateral gas diffusion performance testing of compressed fuel cell carbon paper.

Test function

◆ Bubble Point Pressure

◆ Wet Membrane Flow-Pressure Curve (Wet Curve)

◆ Bubble Point Pore Size (Maximum Pore Size)

◆ Dry Membrane Flow-Pressure Curve (Dry Curve)

◆ Minimum Pore Size

◆ Gas Permeability

◆ Mean Pore Size

◆ Gas Flux

◆ Most Probable Pore Size

◆ Integrity Assessment

◆ Pore Size Distribution

◆ Fiber Membrane Burst Pressure

◆ Liquid Permeability (Liquid-Liquid Method Function)

◆ Lateral Gas Diffusion Performance Evaluation

◆ Liquid Flux (Liquid-Liquid Method Function)

Instrument Standard

| Standard Abbreviation | English Translation |

|---|---|

| GB/T 42269-2022 | Pore Size of Separation Membranes - Gas Permeation Method |

| GB/T 32361-2015 | Pore Size of Separation Membranes - Bubble Point and Mean Flow Pore Method |

| ASTM D6767-02 | Determination of the Opening Characteristics of Geotextiles by Capillary Flow |

| ASTM F316-03 | Describing the Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test |

| ASTM E1288-99 | Determining the Oxygen Transmission Rate (OTR) of Packaging Materials |

| ASTM C-522 | Determining the Water Vapor Transmission Rate (WVTR) of Materials |

| ASTM D-726 | Determining the Air Permeability of Textile Fabrics |

| ASTM D-6539 | Determining the Water Vapor Transmission Rate (WVTR) of Packaging Materials |

| ASTME1294-89 (1999) | Examination of Pore Size Characteristics of Membrane Filters Using Automated Liquid Porometers |

| BS 7591 -4 : 1993 | Porosity and pore size of materials. Part 4 - Determination by water removal |

| BS 3321-1986 | measurement of equivalent pore size of fabrics (bubble pressure test) |

| BS EN240003: 1993 | Determination of pore size by bubble test |

| HY/T 051-1999 | hollow fiber microporous membranes (included in the compilation of membrane technology standards) |

| HY/T 064-2002 | tubular ceramic microporous membranes (included in the compilation of membrane technology standards) |

| HY/T20061-2002 | Hollow fiber microfiltration membrane module |

| GB/T 14041.1-2007 | Hydraulic fluid power - Filter elements - Verification of fabric filter media structural integrity and determination of first bubble point |

| GB/T 24219-2009 | Woven filter cloth - Determination of bubble point pore size |

| GB-T2679.14-1996 | Filter paper and filter board - Determination of maximum pore diameter |

| ISO 2942-2004 | Hydraulic fluid power - Filter elements - Verification of structural integrity and determination of first bubble point |

| DIN ISO 4003-1990 | Permeable sintered metal materials - Determination of pore size by bubble test |

| DIN 58355-2-2005 | Membrane filters - Part 2: Determination of bubble point |

| JISK 3832-1900 | Membrane filters - Bubble point test method |

Technical Parameter

◆ Aperture test range: standard model: 0.012um-500um, (gas-liquid method); large pore model: 0.12um-500um, (gas-liquid method); 5nm-50nm (liquid-liquid method);

◆ Multi-sample cell design for different sizes of samples, special samples can be designed separately;

◆ Equipped with fully automatic vacuum assisted wetting device, which can greatly accelerate the wetting time and improve the test efficiency by more than 50%;

◆ Various wetting liquids are available for different samples to be tested (special wetting liquid BSD15.9 or other wetting liquids);

◆ High-precision dual flow sensors, segmented flow measurement, complementary measurement ranges, automatic switching;

◆ High-precision dual pressure sensors, segmented pressure testing, automatic judgment by the program, automatic switching;

◆ All stainless steel pipelines, metal hard seals, good sealing, high pressure resistance, corrosion resistance;

◆ Detailed instrument operation log display and recording, accurate to the second, full experimental records are traceable

Data Report

Leave Message Get Price