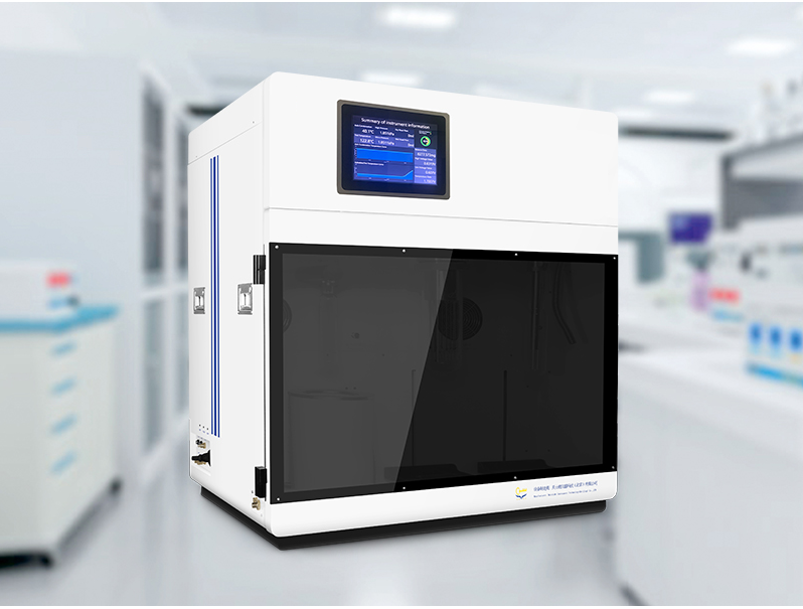

360 rotary tank cleaning equipment, orbital tank washer

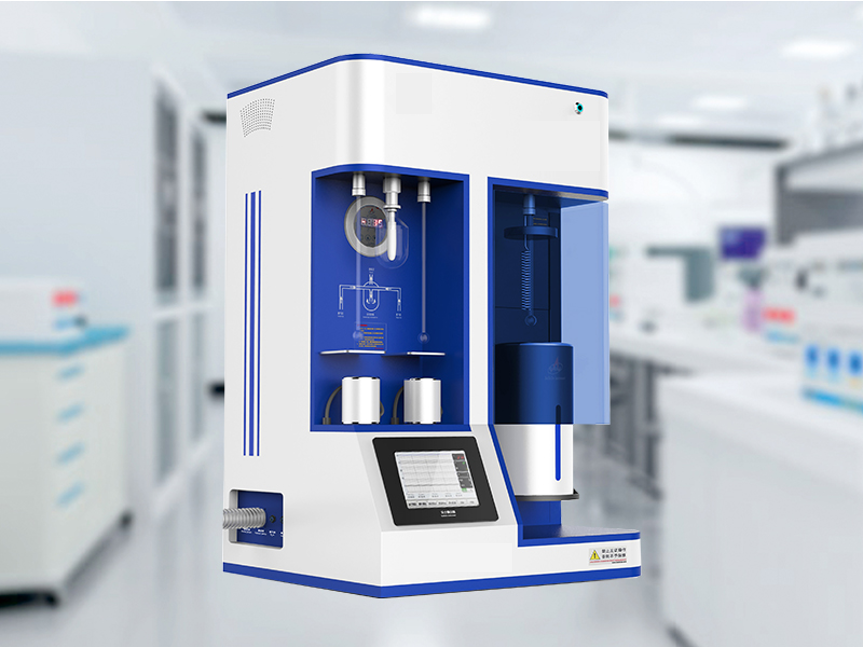

- The standard machine configuration uses two or four nozzles to blast the tank walls and rinse all surfaces. In operation, the unit has to run for the cycle time between on type 8 and 12 min depending on type and pressure. This ensures full cleaning. For extremely difficult applications the cleaning time might have to be extend.

High impact 3D rotary tank washer

Impeller is driven by cleaning fluid and drives internal reduction mechanism. Gear mechanism operates according to set track to realize the revolution and the rotation, thereby achieving 360° thorough cleaning.

● Optimized structural design results in a water jet that produces greater impact

● Excellent sealing design, less than 3% leakage, thus saves cleaning fluid

● Independent gearbox design protects gear from damage and can work in poor water quality

● Adopt high hardness and wear resistant materials, long service life

TApplication:STD DG5 rotary tank washer is suitable for 3D cleaning of small to medium sized tanks,vessel or machines. It is commonly used in beer industry, petroleum, beverage,fuel ethanol, chemical, industrial fermentation,marine and where a high cleaning performance is required.

● Storage tank

● Fermentation tank

● IBC totes

● Fish vessel

● Reactors

●Process vessels

●Underground storage tanks (USTs)

●Rail cars

●Dryers, silos, towers (2d)

Version:

Leave Message Get Price