Safety Shoe Static Pressure and Puncture Resistance Evaluation System

Compliance Standards

- ISO 19643 (Road vehicles - Flexure endurance)

- SAE J1128 (Low Voltage Battery Cable)

- LV 214-2 (Automotive Cable Flexure)

- GMW3191 (GM Wiring Systems)

- JASO D622 (Japanese Automotive Standard)

Technical parameters:

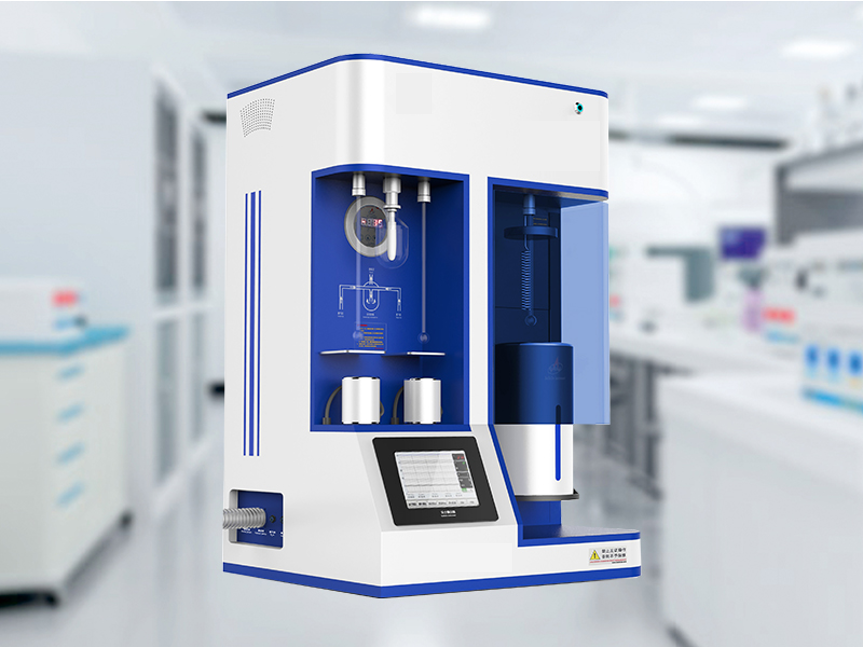

Pressure load cell

Compression force (EN)15±0.1KN

(ANSI)1000±50 —— 10000±50lbs

Compression speed stepless speed regulation

Unit kg, N, and LB can be switched

Pressure shows resolution 1/10000

Maximum load 500kg

Other features include upper limit protection and peak retention, which can automatically shut down

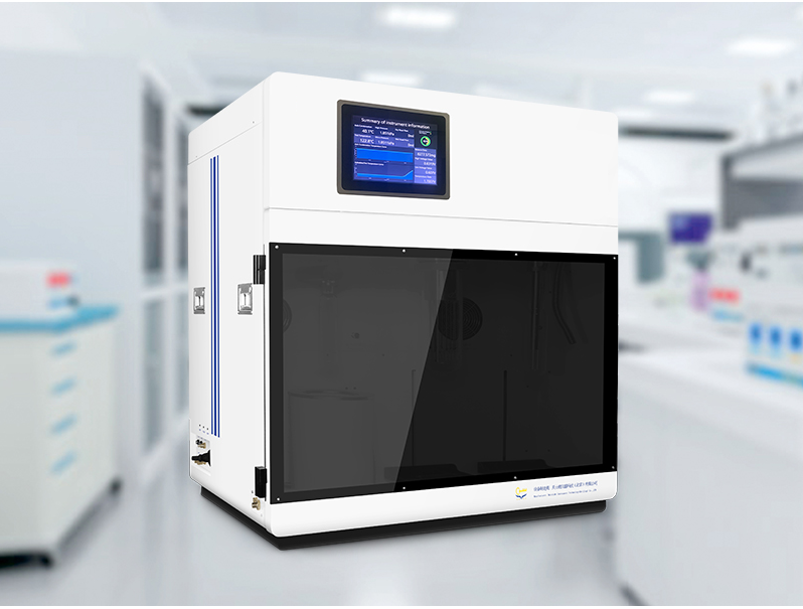

Volume 712×330×828mm

Weight 115kg

Key Features

- Multi-axis bending (X/Y/Z/Rx/Ry)

- Real-time conductor resistance monitoring

- Automated bend radius adjustment

- Thermal cycling during flexure

- Predictive failure analysis

Test Capabilities

| Test Type | Standard | Parameters |

|---|---|---|

| Pure Flexure | ISO 19643 | ±90° @ 2Hz |

| Torsional Bend | LV 214-2 | 180° twist + 90° bend |

| Overmold Flex | USCAR-2 | 5mm displacement @ 1Hz |

Measurement System

- 4-wire resistance measurement (1μΩ)

- Laser displacement sensor (0.01mm)

- Torque cell (±0.1Nm)

- 1000Hz data acquisition

Standard Configuration

- Servo-driven bending actuators

- Adjustable wire clamps (AWG 4-28)

- Basic environmental chamber

- FlexTest Pro analysis software

Automotive Options

- Salt spray corrosion module

- High-voltage arc detection

- Vibration superposition (5-200Hz)

- 3D surface crack detection

Safety Systems

- Emergency motion arrest system

- Load path monitoring

- Safety light curtains

- Over-temperature shutdown

Test Protocol Example (ISO 19643)

- Precondition sample @25°C/50% RH

- Set bend radius to 6×D

- Apply ±90° bending @ 1Hz

- Monitor until 10% ΔR or 50k cycles

- Calculate mean cycles to failure

Maintenance Requirements

- Weekly lubrication of bearings

- Monthly encoder calibration

- Annual load cell verification

- 500h preventive maintenance

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price